Let Kai build at Berkeley

Berkeley is where engineering meets people — and that's where I want to build.

I want to design intelligent physical systems that people trust, wear, and rely on every day.

01

Context

The future of human-computer interaction is moving into physical space. We're moving beyond screens and keyboards toward devices that understand context, anticipate needs, and integrate seamlessly into daily life.

I see this shift happening in wearables, ambient devices, and assistive technology, where the hardware itself becomes the interface. The challenge isn't just building something that works in a lab; it's designing systems that people actually want to wear, trust, and rely on day after day.

This is where mechanical engineering meets human-centered design. It's about understanding thermal constraints, material properties, ergonomics, and manufacturability, not as afterthoughts, but as core design requirements from day one.

02

Motivation

Prototypes don't become products. I've learned this firsthand building hardware: what works on a breadboard fails in real-world use. What looks good in CAD breaks after a week of wear. What seems intuitive in testing becomes frustrating when people are tired, distracted, or just trying to get through their day.

The gap between prototype and product is massive:

- Reliability: Devices need to work consistently, not just when conditions are perfect.

- Ergonomics: Comfort over hours and days, not just minutes. Form factors that feel natural, not intrusive.

- Manufacturability: Designs that can be produced at scale with consistent quality and reasonable cost.

- Trust: Users need to believe the device will work when they need it most, which means it has to work every time.

Most hardware projects fail at this transition. They solve the technical problem but miss the human one. I want to bridge that gap.

03

How I've Prepared for Berkeley

Onvoice (Founder)

Built a live-event assistant that streams speech to attendees in real time for accessibility and engagement. Shipped pilots across multiple organizations, participated in GC Angels Accelerator (12% acceptance rate), received ~£5.75k funding, and iterated based on real user feedback.

Outcome: Product-led iteration with real users, understanding the gap between technical capability and user needs.

Wearable AI Microphone Prototype (Project)

Built a wearable device with ESP32-S3 + INMP441 microphone, focusing on always-available interaction. Electronics stack includes PCB design, battery management, power regulation, touch sensors/LEDs, USB-C + CP2102, boot control. Device communicates with PC/phone app.

Key realization: Prototypes are easy. Production-ready devices require mechanical design, thermal management, tolerances, materials, ergonomics, reliability, and manufacturability, all things I need to learn systematically.

LGS TECH (Founding Electronic Engineer)

(Applied power, sensing, and reliability at scale)

Worked on electronics and system design for safety-critical, long-lifecycle hardware. Contributed to PCB design, enclosure constraints, and system integration where small electrical decisions propagated into manufacturability, servicing, and long-term reliability.

Outcome: Learned how industrial hardware is less about clever circuits and more about traceability, robustness, failure modes, and design decisions that survive years, not demos.

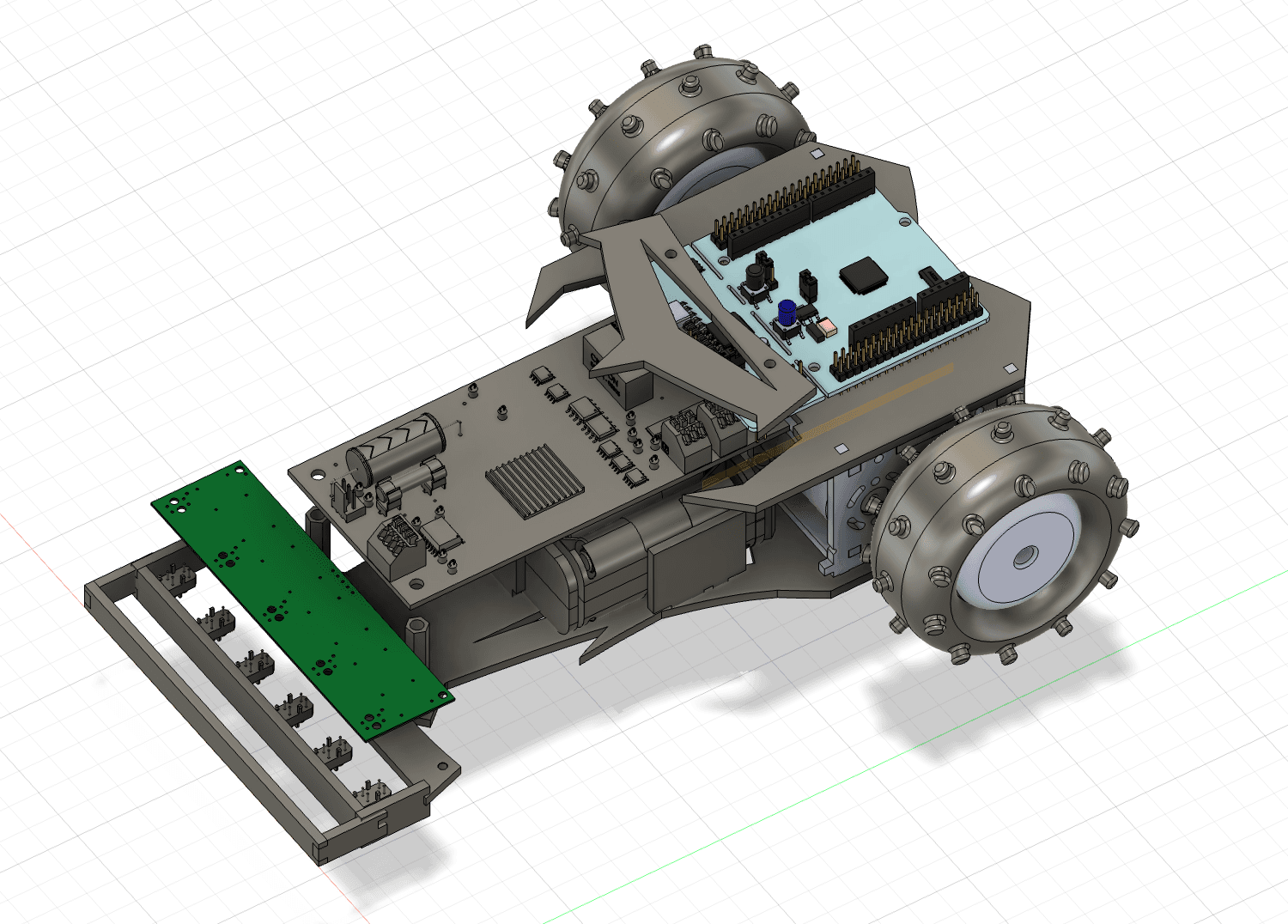

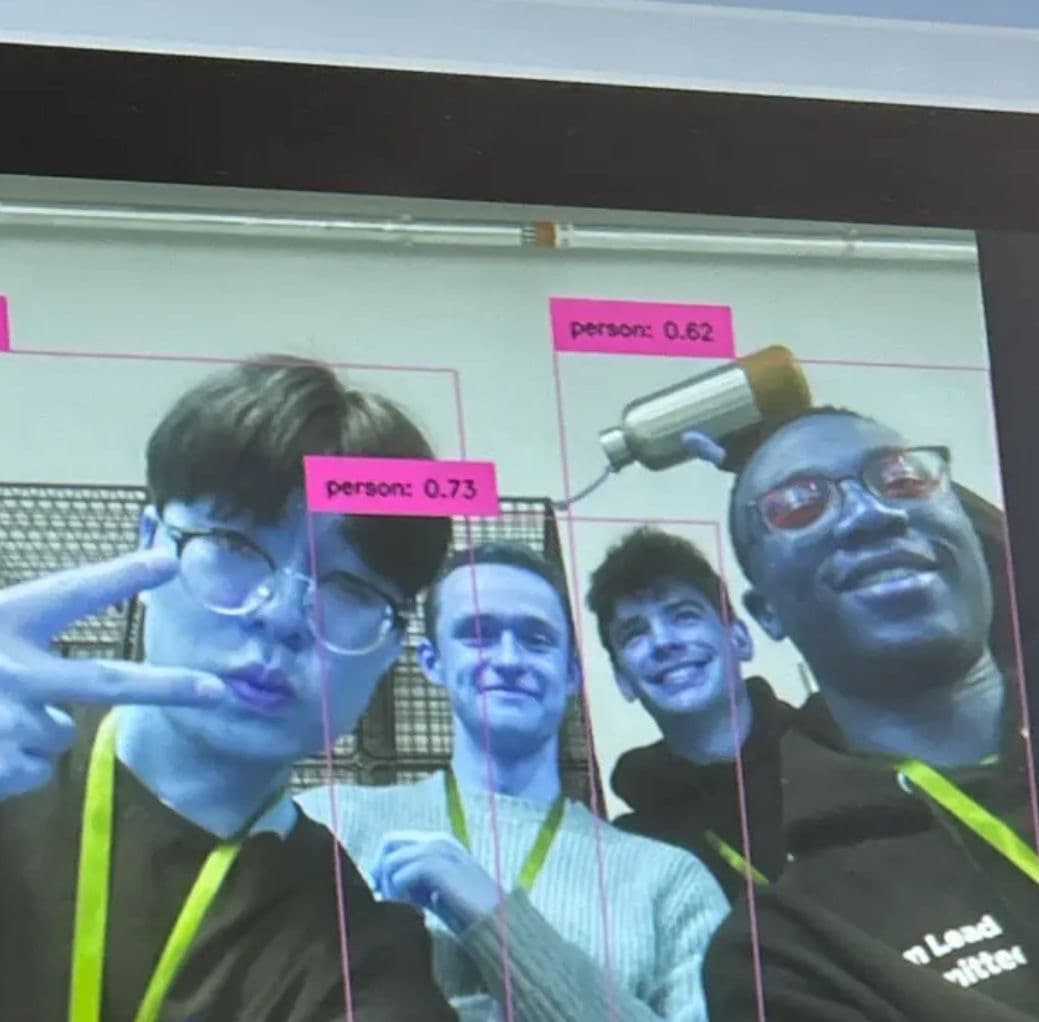

Autonomous Buggy (Embedded System Competition)

(Sensing, control, and real-world autonomy)

Built and iterated on an autonomous buggy platform integrating embedded control, sensor fusion, and real-time decision making. Worked across firmware, electronics, and system integration to get a physical agent to behave reliably in an unpredictable environment.

Key realization: Autonomy breaks at the boundaries: timing, calibration, noise, and physical dynamics matter more than algorithms. Real systems force you to respect latency, uncertainty, and hardware limits.

Undergraduate Academic Performance

BEng (Hons) Electronic Engineering, University of Manchester

Outstanding performance in embedded systems, digital design, and electronics:

04

Why Berkeley

UC Berkeley's MEng Mechanical Engineering with a Product Design focus is exactly what I need to bridge the gap between prototype and product.

The Courses

- ME 290KA - Innovation Through Design Thinking: Systematic approach to human-centered design.

- ME 292C - Human-Centered Design Methods: Methods for understanding user needs and validating designs.

- ME 290U - Interactive Device Design: Designing devices that respond to human interaction, exactly what I'm building.

- ME 235 - Design of Microprocessor-Based Mechanical Systems: The intersection of embedded systems and mechanical design, my core interest.

The Ecosystem

Jacobs Institute / Jacobs Hall: The making and design ecosystem where I can iterate on my wearable hardware with access to professional tools, materials, and expertise.

BEST Lab: A research and design community focused on human-centred design and intelligent physical systems. The lab's work on wearables and IoT aligns closely with my interest in building AI-enabled hardware that integrates sensing, computation, and user interaction in a seamless, human-first way.

SkyDeck / Sutardja Center: The startup ecosystem where I can stress-test my product ideas, validate with real users, and explore commercialization pathways.

I want to contribute as someone who can bridge embedded engineering and human-centered product realization. I've built the electronics and firmware; now I need the mechanical engineering depth to make it manufacturable, reliable, and truly human-centered.

05

What I'll do there

Build

Iterate on my wearable hardware with human-centered evaluation and mechanical refinement. Use Jacobs Hall and BEST Lab to push beyond prototype constraints: proper thermal management, ergonomic form factors, material selection, and assembly design.

Validate

Run pilots with real users, define success metrics (comfort, trust, reliability), and iterate based on feedback. Use Berkeley's design methods courses to structure this validation process systematically.

Realize

Design for manufacturability: packaging, assembly, robustness. Understand the constraints and trade-offs that turn a working prototype into a scalable product. Explore commercialization pathways through SkyDeck and Sutardja Center.

PROJECTS

Relevant Projects

Autonomous Line-Following Buggy

ARM-based autonomous vehicle system designed for high-performance operation under real constraints. University research project focused on system integration.

Wearable AI Microphone Prototype

ESP32-S3 based wearable device with always-available interaction, focusing on seamless human-computer interface.

BagAlert (Sony Hackathon - 1st Place)

A campus-focused loss-prevention system that detects unattended bags and alerts the correct owner in real time.

Onvoice

Live-event assistant that streams speech to attendees in real time for accessibility and engagement.

Branchify

A student-only marketplace designed to make buying and selling second-hand items easier, safer, and more trusted on university campuses.

Hardware Lifecycle Engineering - Light Guiding Systems Technology

Worked in a professional hardware startup environment contributing across electronics, mechanics, and system integration.

Robot Fighting Competition - Mechanical Redesign Under Failure

A competitive fighting robot designed, tested, failed, and redesigned through mechanical analysis and iteration.

Coupang Hackathon - User-Centered Product Concept

A product concept developed to address Coupang's limited penetration among Taiwanese youth through short-form video platform design.

AWARDS & RECOGNITION

Awards & Recognition

Autonomous Line-Following Buggy Competition - 1st Place

Achieved fastest lap time and highest technical score among 50 teams in EEE second year. Designed and fabricated an ARM-based autonomous vehicle system with custom PID control algorithm, achieving seamless integration of mechanical chassis, sensing systems, and embedded firmware. full report

Sony Hackathon - 1st Place

Built BagAlert, an AI-powered smart surveillance system for preventing theft of unattended belongings. Integrated ESP32 + RFID, Sony IMX500 AI camera, real-time detection, and live alert dashboard. official post from sony • hackster.io

Google Developer Student Clubs Hackathon - 1st Place

Developed accessibility-focused input systems using hand-tracking and eye-tracking. Built a scanning keyboard enabling text input with minimal physical interaction.

Masood Entrepreneurship Centre Startup Weekend - 2nd Place

Co-developed Branchify, a student marketplace focused on trust and sustainability. Progressed from problem discovery to business model and pitch within a single weekend.

GC Angels Accelerator

Selected into accelerator (12% acceptance rate) and received funding for Onvoice. linkedin post

ASK KAI

Ask me questions!

Ask me about my projects, goals, or why Berkeley. I'll answer based on what I've shared here.

Ask me anything about my projects, goals, or why Berkeley.

CONTACT

Get in touch

If you're reading this, thank you for taking the time to learn about my work and goals. I'm excited about the possibility of contributing to Berkeley's mechanical engineering program and learning from the incredible community there.

I'd love to hear from you, whether you have questions, want to discuss my projects, or just want to connect.